Have you ever wondered what is made from our ABRAMS PREMIUM Steel®?

We at ABRAMS Industries® value the cooperation with our customers very much and it always delights us to see what end products are created from our PREMIUM steel.

ABRAMS Industries® offers 70 materials in 32,629 dimensions and saws, mills and grinds to the customer’s desired dimension before the precision steel reaches them. This makes it even easier for them to further process the steel grade and thus save unnecessary storage costs.

As diverse as our steel range is, steel itself is also a versatile and changeable material.

It is not only suitable for large industrial projects, e.g. in tool and mould making, but also for the smallest detail projects, such as jewellery making.

In cooperation with Mr. Boris Müller, founder of Erosch jewellery, we have accompanied the journey of our PREMIUM 1.4301 from our shelf in production, to the manufactured chain pendant.

Which metal is suitable for jewellery making at all?

Which stainless steel is used for jewellery?

PREMIUM steel 1.4301 is a corrosion-resistant, austenitic chromium-nickel steel that is easy to work with and has an attractive appearance when polished to a mirror finish. This steel material has good deep-drawing properties, is weldable and wear-resistant, which makes it predestined for manufacturing fashionable jewellery.

Order quality steel from ABRAMS Industries®

Orders are received daily at our headquarters in Osnabrück and are then forwarded to our in-house production department.

This was also the case with the order from Erosch Manufaktur. The order was processed quickly: PREMIUM 1.4301 in the in-house €co-Präz® version produced to Mr. Müller’s requested dimensions.

The journey begins: €co-Präz® customized.

First, the right material is

selected according to the

order.

The raw

panel is

sawn…

… and milled to

the desired dimensions

of our customer.

The processed material

is then subjected to a

quality inspection.

Shipping of the steel

ABRAMS PREMIUM stainless steel chain pendant

Shipping of the steel

The material is carefully

wrapped in

protective packaging …

… and labelled with the ABRAMS banderole. Then it’s off to the customer!

ABRAMS PREMIUM stainless steel chain pendant

Just one day after dispatch,

Mr. Boris Müller personally

accepts the parcel.

The material is

inspected and passes

the inspection.

As a steel supplier, we at ABRAMS Industries®, are always pleased to meet the demands of Erosch!

What is erosion in the manufacturing of stainless-steel chain pendants?

During the Starthole erosion the holes for the eyelets are made, which is important to be able to attach the pendant to a chain.

The steel chain pendants are eroded from the solid on the wire eroding machine. The side with the letter is the first one to be cut.

The material is then rotated 90° and the heart is eroded.

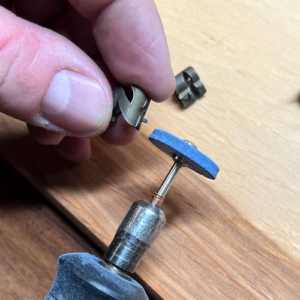

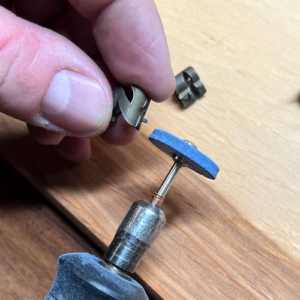

After the pendants have been eroded, the eyelets are rounded off by hand with a grinder.

During the Starthole erosion the holes for the eyelets are made, which is important to be able to attach the pendant to a chain.

The steel chain pendants are eroded from the solid on the wire eroding machine. The side with the letter is the first one to be cut.

The material is then rotated 90° and the heart is eroded.

After the pendants have been eroded, the eyelets are rounded off by hand with a grinder.

Now the pendants are electropolished and checked individually and precisely by hand.

The silver pendants are ready. If desired, they can be gold-plated …

… hard gold plated with real gold.

Rosé- …

… or yellow gold.

Now the pendants are electropolished and checked individually and precisely by hand.

The silver pendants are ready. If desired, they can be gold-plated …

… hard gold plated with real gold.

Rosé- …

… or yellow gold.

After a final quality check, the pendants, with or without a chain,

are packaged.

The parcel is then

sent to the proud

new owners.

What does our customised steel mean for the industry in Germany?

Collaborations like this are particularly important to us at ABRAMS Industries® because it is essential for us to work together with other companies. This way, we not only support each other, but also drive the domestic economy.

We are very happy that we are cooperating with Erosch and that this wonderful blog article was able to come to life, which is intended to give an insight into the further use of our steels. A huge thank you to Boris Müller for providing the photos and the great cooperation, which we really appreciate.

Steel can be so much more than most people think. That’s why it makes us even happier to share such a success story, to offer an even better picture of our industry and to give a stage to the diversity of our products.

Additional info: How do I clean jewellery made of stainless steel?

Since it is a corrosion-resistant steel, it is advisable to clean the pendants carefully with water and a little soap. Afterwards, it is important to rinse the piece thoroughly so that the protective layer is not attacked and the piece of jewellery remains like new for as long as possible.